FlexHead® Duct Sprinkler Connections No Leaks. No False Alarms. No Downtime.

FlexHead flexible sprinkler systems have been protecting exhaust ducts in semi-conductor/ electronics facilities for more than fifteen years with no reported failures or leaks, and no sprinkler related downtime. During normal operation, patented FlexHead technology contributes to productivity by allowing the process to continue even during routine maintenance.

FM-Approved FlexHead Sprinklers Install in Minutes

FlexHead sprinkler systems come complete with a flexible, stainless-steel hose, sprinkler head of choice, mounting block, and head-protecting polybag with gasket that prolongs the life of the sprinkler head. Mounting blocks are available for all types of exhaust ducts. Typical installations take about 10 minutes per head. Total cost is less than traditional hard-pipe

installations, which take up to four hours per head, and require an expensive, separate access port for inspection.

Factory Mutual has approved FlexHead’s complete exhaust duct sprinkler system, including the mounting block. So, out of the box, installations meet insurance requirements. Traditional hard-pipe installations must be individually inspected.

FABs Keep Running During Scheduled Maintenance

In addition to simplifying installation, FlexHead sprinkler design also streamlines inspection and maintenance. By simply releasing four hex nuts, the sprinkler head/ polybag can be pulled out of the duct for direct visual inspection without interrupting FAB/plant operations.

Start to finish, preventive maintenance takes about ten minutes per head and costs a fraction of hard-pipe inspection. In fact, many facilities have been retrofitted with FlexHead sprinkler systems for about the cost of one hard-pipe inspection cycle-getting more reliable protection at a much lower ongoing cost.

Regardless of Material, All Ducts Require Some Sprinkler Protection

FM regulations require sprinkler protection in all duct work regardless of the duct material used. Sprinklers are required if the duct rises more than the specified height for the material used, passes through a firewall, contains combustible fumes, if the build-up of combustible residues is likely to exceed threshold levels, or if the tool being vented is flammable. If these conditions are ignored, and sprinklers are not installed, insurance coverage may be void. Why take that chance, especially since you have to run a sprinkler main anyway?

Features and Benefits

Combining patented FlexHead sprinkler systems with the best corrosion resistant duct material, costs less than half of any non-sprinkler duct materials and provides the most cost-efficient choice in exhaust duct systems. FlexHead sprinkler systems also offer:

- Labor-saving, simplified installation takes minutes instead of hours .

- Patented polybag/ gasket assembly creates clean mini-environment for sprinkler heads within ducts, prolonging the life of sprinkler heads, and prevent ing production downtime caused by false alarms

- Wide variety of mounting blocks are available to accommodate all types of exhaust ducts

- FM-approved right out of the box. Meets all insurance requirements

- Eliminates need for costly access panel mounted on duct as is mandatory with hard-pipe sprinklers

- Preventive maintenance takes 10 minutes-with NO required FAB shutdown-unlike hard-pipe

- Flexible hoses allow for independent motion (sway) between duct and water main to compensate for duct vibration and during possible seismic activity – eliminating potential leaks, and allow for multiple design choices and flexibility during retrofit and expansion

Call For More Information

Planning the best fire protection requires careful consideration. If you would like more information on how FlexHead flexible sprinkler systems are the easiest, most reliable, and most cost-effective systems available, please call (800) 829-6975 today! Or visit our website at www.flexhead.com.

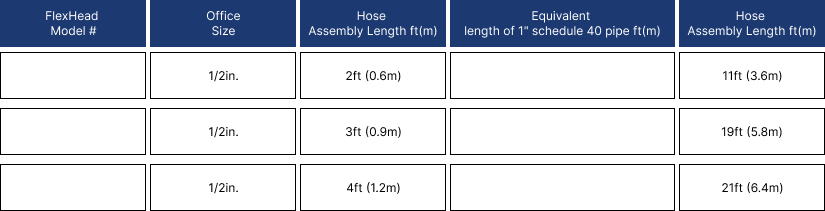

FRICTION LOSS

“XX” represents the model number. For example: 1024 is FlexHead model number for 1000 Series.

1000 Series is limited to Fiberglass Reinforced Plastic (FRP) exhaust ducts.

1100 Series is limited to metal exhaust ducts.

1200 Series is limited to Polypropylene Plastic exhaust ducts.

1300 Series is limited to Polyvinyl Chloride Plastic (PVC) exhaust ducts.

Each FM-approved, ready-to-install sprinkler system is pressure- and leak-tested prior to shipping and comes complete with a flexible stainless-steel hose, reducing coupling integrated into top mounting flange, manufacturer applied wax coated sprinkler head, gasket with dual poly bag assembly and bottom mounting block.