Kitchen Fire Suppression System

Leeden Fire Safety PL is now the distributor for Lehavot (Advanced Fire Protection System) full range of “KITCHENShield” WCK Kitchen Fire suppression system, a UL300 listed products.

KITCHENShield

Electric and gas-operated cooking appliances in the kitchen use large amounts of flammable ingredients and are in particularly high danger of ignition and fire outbreak.

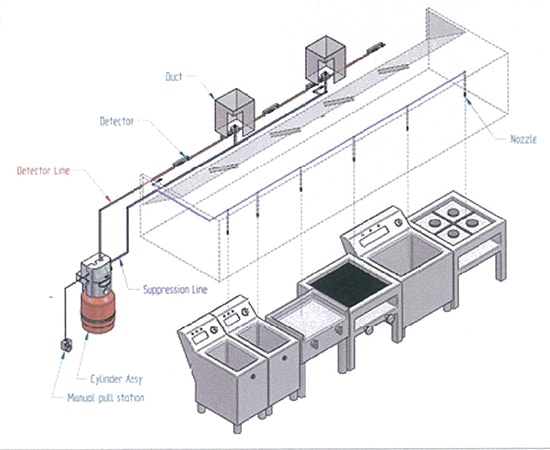

The WCK Kitchen Fire Suppression System is an automatic pre-engineered system, designed to protect the kitchen area including ducts and plenums, as well as all cooking appliances such as deep fat fryers, woks, griddles, salamanders, chain broilers and more.

This system caters to the needs of both small and large kitchens such as those in hotels, restaurants, hospitals and public institutions.

1. Nozzles are arranged to offer maximum coverage of all installations.

2. Heat detectors installed within the plenum and triggered only during fire.

3. The system distributes the extinguishing agents over all protected areas and interrupts the supply of gas or electricity.

4. Temperature detection level can be custom-suited to each application.

Features and benefits

- Fast Detection – Quickly detects fires to minimize damage and injuries.

- Stainless Stell Friendly – The extinguishing liquid has a low acid level (below pH:9) and protecting stainless steel surfaces.

- Dual Action – Simultaneously extinguishes the fire while interrupting the energy supply.

- Environmentally Friendly – Water-based agent not harmful to the environment.

- Custom Made Solutions – Custom designing modelling, testing and manufacturing of fire suppression systems to meet customers’ diverse requirements.

- Proprietary Technology

- Fast Installation

- Flexible Mounting Of The Discharge Piping Distribution

- Simple Design Of The Discharge Piping Distribution, Flexible Mounting Of The Manual Pull Station And Gas Valve

- Mechanical System – Does not require N2 or CO2 cylinder to operate the dry chemical agent.

- Multiple Cylinder – Largest amount of cylinders (up to 6 units) and longest distance between them in one system in the market.

- No Crimping Needed Inside The MR

Kitchen Fire Suppression System

Simple and easy to maintain system effectively protects kitchens in hotels, restaurant and public institutions with a high risk of fire.

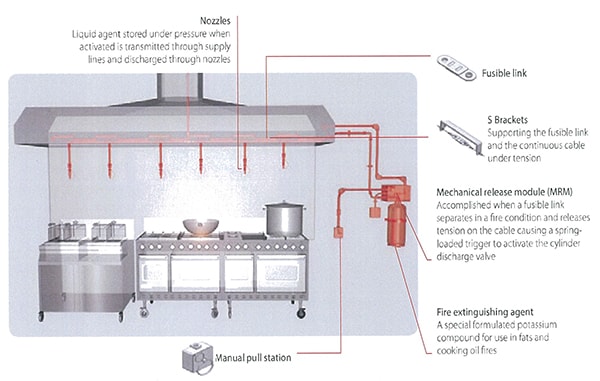

The system protects the ducts, hood and cooling appliance areas using a continuous cable that connects all cooking devices with strategically placed detectors. Each detector is comprised of four parts: detectors, a bracket, two “S” links and a fusible link.

As the heat builds the fusible link will separate at a predetermined temperature relieving tension on the cable and activating the system.

- The system is operated automatically or manually according to customer requirements.

- Temperature detection levels can be adjusted to suit the application.

- Heat detectors are installed within the plenum and are triggered only during fire, while nozzles are arranged to offer maximum extinguishing coverage of all cooking application.

- A manual pull stations allows immediate response capabilities backing up the automatic suppression system.

- The system distributes the extinguishing agent over all protected areas, while interrupting the energy supply of gas and electricity for maximum protection against re-ignition.

- Potassium hydroxide phosphate is used to extinguish cooking oil/grease fire. Upon contact with the oil, the liquid creates foam, preventing oxygen from reaching the fire and cooling the area.

- All system parts are attractively styled, so as not to detect from the look of the kitchen, while the design ensures that kitchen workspace is not disrupted.

- After system operation, the kitchen can be ready to be re-utilized within minutes.

- The system can be recharged and ready to work in a very short period of time after discharge.

System components

|

Fusible Link Melted by heat, the two halves of the link will separate operating the extinguishing agent. |

|

Detector Bracket Supporting the fusible link and the continuous cable under tension. |

|

Mechanical release module (MRM) Accomplished when a fusible link separates in a fire condition and releases tension on the cable causing a spring-loaded trigger to activate the cylinder and discharge valve. |

|

Nozzles Liquid agent stored under pressure when activated in transmitted through supply lines and discharged through nozzles. |

|

Manual Pull Station Each Lehavot WCK system is equipped with at least one manual pull station providing a means of activating the system manually if required. |

|

Extinguishing agent The Lehavot extinguishing agent is based on a potassium compound that extinguishes cooking oil fires by means of colling and saponification. |

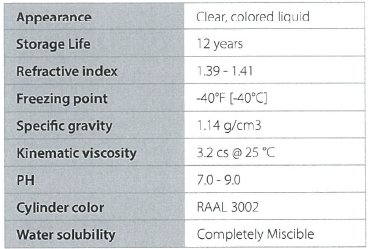

Technical Parameters

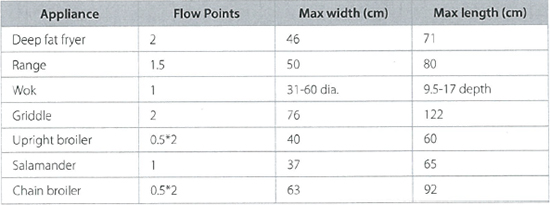

System Coverage Capabilities

Appliance / Converage