SUPALUX

Introduction

SUPALUX consists of a calcium silicate matrix of reinforced fibres and fillers, 100% asbestos free The SUPALUX formula is cured to form a dimensionally stable board through an autoclave process where the board is subject to pressurised steam and high temperature. The result is a board that is lightweight, has a high impact resistance, high fire resistance, and with all the excellent qualities that SUPALUX has been delivering to a loyal following of customers and end users for more than 25 years.

EFFECT OF MOISTURE

Saturate a SUPALUX board in water and allow it to dry and see the return to its original condition with almost no degradation. Moisture and dampness has no permanent effect on the mechanical or fire performance of the material. It is therefore possible to install SUPALUX at any time in the building programme.

IMPACT RESISTANT

A SUPALUX wall construction has fulfilled all the severe duty requirements for impact, crowd pressure, deflection and multiple cycles of door slam in accordance with British Standard 5234, proving its excellent impact resistance.

THERMAL

SUPALUX has a very low thermal conductivity of 0.21W/mk

BIOLOGICAL

SUPALUX does not attract insects or vermin and does not support mould growth.

CHEMICAL

SUPALUX is not affected by brine or dilute chlorine and other chemical solutions. It is also resistant to low concentrations of most acids, alkalis, bleaching agents and solvents.

COMPATIBILITY

SUPALUX is compatible with most building materials, non-caustic and will neither promote corrosion nor affect bituminous compounds.

The surface of SUPALUX can readily receive many forms of architectural treatments from painting, wallpapering, waterproofing membrance, tiling, and other common aesthetics finishes. It is advised that the manufacturers instructions of these treatments should always be strictly adhered to at all times.

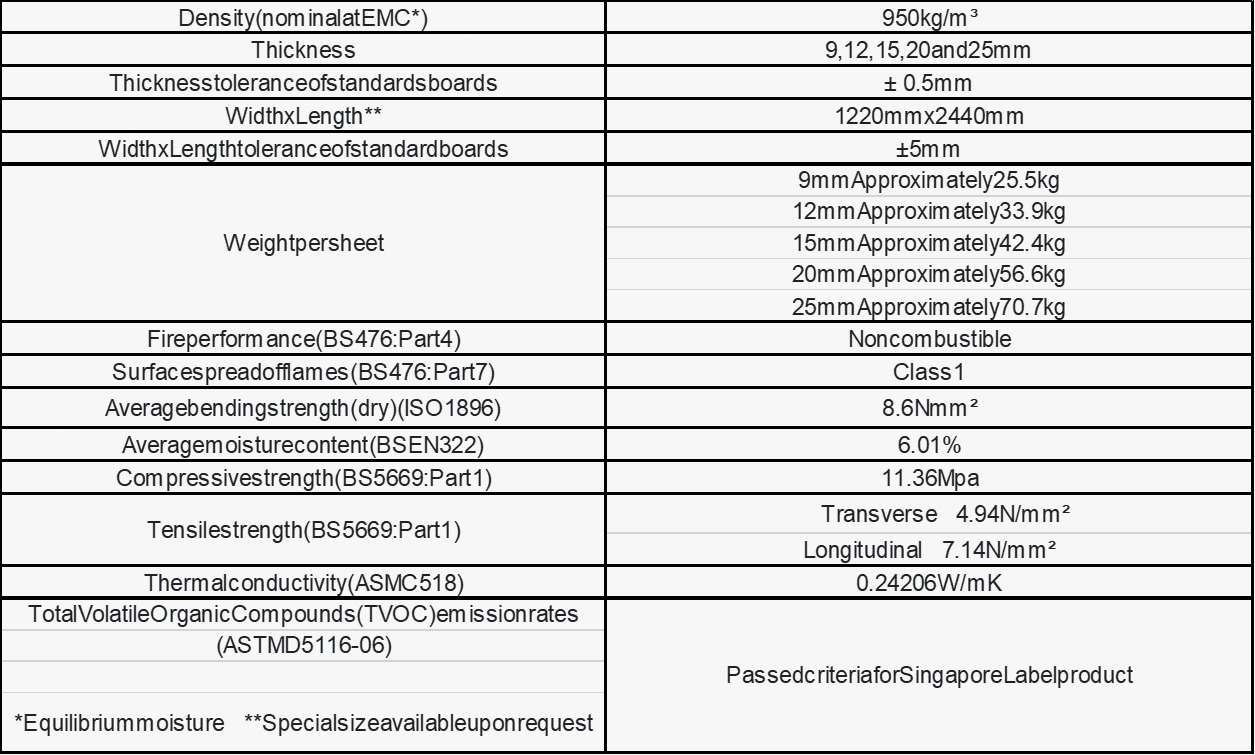

The properties in above tables are mean values given for information and guidance only. If certain properties are critical for the application, please contact your nearest Intumex Asia Pacific office.

SUPALUX is manufactured under a quality management system certified in accordance with ISO9001: 2000 Certification, and in accordance with the environment standards of ISO14001. For further technical information, please consult Intumex Asia Pacific.

As for all products containing quartz, such as concrete and clay, this product will also release dust containing quartz particles when it is mechanically machined (cutting, sanding, drilling). Inhalation of high concentrations of dust can irritate the respiratory system. Dust can also irritate the eyes and/ or the skin. The inhalation of quartz containing dust, in particular high concentration of line (respirable) dust or over a prolonged period of time can lead to lung disease (silicosis) and an increased risk of lung cancer. Avoid the inhalation of dust by using machinery with dust extraction. Guarantee adequate ventilation on the work floor. Avoid contact with the eyes and skin and avoid inhalation of the dust by wearing appropriate personal protection gear (safety goggles, protective clothing and dust mask). For more information please check the material safety data sheet, available upon request from

Terminology of Fire Resistance

FIRE RESISTANCE OF STRUCTURES

Fire resistance is not a property of a material but the performance of a complete element of structure which will generally be comprised a number of different materials and components. The fire resistance of load bearing and non load bearing partitions and ceilings are determined by a test in accordance with the criteria of British Standard 476: Part 21 and 22: 1987 respectively.

Specifications shown in this document have been tested or assessed by independent authorities for compliance with International Standards. Additional testing has been carried out worldwide.

A fire resisting construction can be any one of a number of elements in a building, for example a wall, ceiling, duct, protected shaft or cavity barrier. This document gives details of some of the constructions used in fire resisting applications. For full details on many other fire resistance constructions please refer to Intumex Asia Pacific.